A servo pressure regulator reacts to changes in pressure, offering precise and responsive control in various applications. This article delves into the inner workings, types, applications, maintenance, design considerations, and advancements of servo pressure regulators.

Servo Pressure Regulators: Overview

Servo pressure regulators are control devices designed to maintain a constant output pressure regardless of variations in flow rate or upstream pressure. They achieve this by using a feedback loop to monitor and adjust the output pressure, ensuring precise and stable pressure regulation.

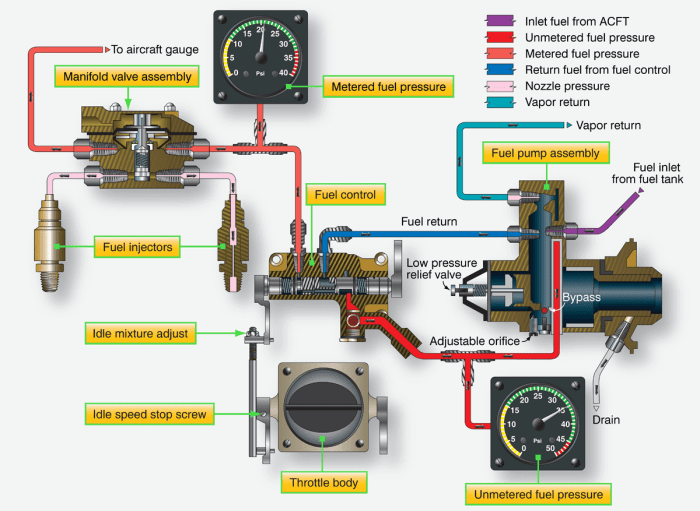

Components of a servo pressure regulator typically include a pilot valve, a diaphragm or piston, and a spring. The pilot valve controls the flow of fluid into or out of the regulator, while the diaphragm or piston actuates the valve based on the feedback signal.

The spring provides a reference pressure against which the output pressure is compared.

Servo Pressure Regulators: Types

Direct-Acting Servo Pressure Regulators

Direct-acting servo pressure regulators use the output pressure directly to actuate the pilot valve. They are compact and have a fast response time, but they can be sensitive to pressure fluctuations.

Indirect-Acting Servo Pressure Regulators

Indirect-acting servo pressure regulators use a separate pilot pressure to actuate the pilot valve. They are less sensitive to pressure fluctuations, but they have a slower response time and require a separate pilot pressure source.

Proportional Servo Pressure Regulators

Proportional servo pressure regulators use a proportional control algorithm to adjust the output pressure. They provide precise pressure regulation and can handle large flow rate variations.

Servo Pressure Regulators: Applications: A Servo Pressure Regulator Reacts To Changes In

Hydraulic Systems

Servo pressure regulators are widely used in hydraulic systems to control the pressure of the hydraulic fluid. They ensure that the pressure remains within the specified range, protecting components from damage.

Pneumatic Systems

In pneumatic systems, servo pressure regulators are used to regulate the pressure of the compressed air. They maintain a constant pressure, ensuring that pneumatic tools and actuators operate correctly.

Process Control

Servo pressure regulators are also used in process control applications to regulate the pressure of gases or liquids in industrial processes. They help maintain the desired pressure for optimal process efficiency.

Servo Pressure Regulators: Maintenance and Troubleshooting

Maintenance

- Regularly check the regulator for leaks or damage.

- Clean or replace the filter element as needed.

- Calibrate the regulator periodically to ensure accurate pressure regulation.

Troubleshooting, A servo pressure regulator reacts to changes in

- If the output pressure is too high, check the pilot valve for clogging or damage.

- If the output pressure is too low, check the diaphragm or piston for wear or damage.

- If the regulator is unstable or oscillating, check the spring for damage or the pilot valve for sticking.

Servo Pressure Regulators: Design Considerations

When designing a servo pressure regulator, several factors need to be considered, including:

- Required pressure range

- Flow rate requirements

- Response time

- Sensitivity to pressure fluctuations

- Environmental conditions

Trade-offs must be made between these parameters to achieve the optimal design for the specific application.

Servo Pressure Regulators: Advancements and Future Trends

Advancements

Recent advancements in servo pressure regulator technology include:

- Digital control algorithms for improved accuracy and stability

- Compact designs for space-constrained applications

- Self-diagnostic capabilities for easier troubleshooting

Future Trends

Future trends in servo pressure regulation include:

- Increased use of wireless technology for remote monitoring and control

- Integration of artificial intelligence for predictive maintenance and optimization

- Development of new materials and manufacturing techniques for improved performance and reliability

Questions and Answers

What is the primary function of a servo pressure regulator?

To maintain a constant output pressure regardless of variations in the input pressure or flow rate.

What are the different types of servo pressure regulators?

Direct-acting, pilot-operated, and electro-hydraulic.

What are the advantages of using a servo pressure regulator?

Precise pressure control, fast response time, and stability under varying conditions.